Typical Cases

- Polysilicon

Project Name: High-purity polysilicon Project

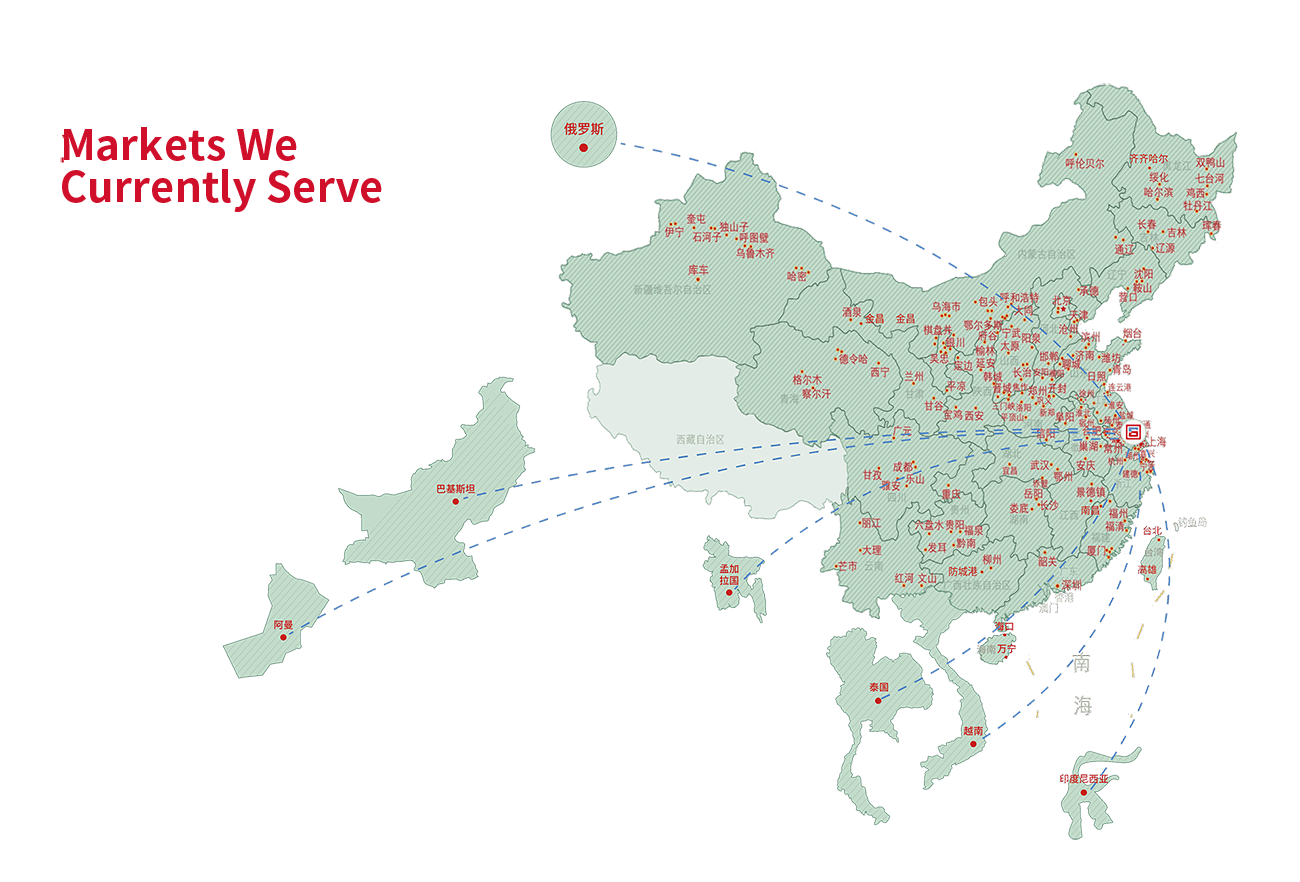

Project Location: Sohar Freezone, Oman

Ndustry: Polysilicon

Project Overview:

The project plans to construct an annual production capacity of 100,000 tons of high-purity polysilicon, with operations expected to commence by the end of 2025. Upon completion, it will account for approximately 4.4% of the global polysilicon market, making Oman the world's second-largest polysilicon producer. As the first polysilicon plant in the Middle East, the project will fill a gap in the local industrial chain and support Oman's economic diversification strategy. Since the commissioning phase, Gosun has been collaborating with this project, handling the plant's circulating water system. The project has been operating stably and the production has been running well.

- Fertilizer

Project Name: Shagor Fertilizer Project, Bangladesh

Project Location: Shagor Region, Bangladesh

Industry: Fertilizer

Project Overview:

The project was officially signed in December 2011 by China National Complete Plant Import-Export Corporation (CNCP) and Bangladesh Chemical Industries Corporation (BCIC). The full-plant performance test was completed by the end of 2015, and the construction phase was successfully concluded in February 2016. The project has a designed annual production capacity of 300,000 tons of synthetic ammonia and 520,000 tons of large-granule urea. It is Bangladesh's first fertilizer plant to achieve its production targets in the year of commissioning. Gosun has supplied its environmentally friendly water treatment chemicals to this project. All system indicators have met national standards, ensuring stable production operations.

- Steel

Project Name: Nickel-iron smelting project

Project Location: Delong Industrial Park, North Morowali, Central Sulawesi Province, Indonesia

Industry: Steel

Project Overview:

This nickel-iron smelting project is independently invested and constructed by Jiangsu Delong Nickel Industry Co., Ltd. of China. It employs the Rotary Kiln-Electric Furnace (RKEF) process and is equipped with 36 nickel-iron production lines, each with a daily processing capacity of 1,300 tons of laterite nickel ore. The smelter is supported by a 2×150MW coal-fired power plant, achieving an energy self-sufficiency rate of over 85%. The annual production capacity reaches 1.8 million tons of nickel-iron. Gosun has been responsible for the project under a comprehensive chemical supply contract, ensuring stable operation. The on-site system has run smoothly, with dedicated service personnel maintaining clear records and providing timely, professional monthly and annual reports, earning consistent recognition from the client. Throughout the service period, Gosun’s technical team has proactively offered numerous optimization recommendations for the site. Additionally, Gosun has installed and upgraded various equipment and facilities, further enhancing operational efficiency - a contribution that has been highly praised by the client.

- Chemical

Project Name: PLA and PBAT Project

Project Location: Kendal Industrial Park, Semarang, Central Java Province, Indonesia

Industry: Chemical

Project Overview:

Invested by Yangzhou Huitong Technology Co., Ltd., the project is designed with an annual production capacity of 100,000 tons of PLA (Polylactic Acid) and 100,000 tons of PBAT (Polybutylene Adipate Terephthalate). Gosun took charge of the circulating water treatment system of this project. In compliance with local environmental regulations and on-site process technical requirements, we have continuously optimized and improved the chemical formulations. Supported by our dedicated on-site technical service team, the circulating water system has maintained high-efficiency and stable operation, earning strong recognition from the client.

Typical Customers